300mm Epitaxial Wafer

Wafer

Semiconductor Value Chain

-

Poly Silicon

Poly Silicon

-

Ingot / Wafer

Ingot / Wafer

-

Patterned Wafer

Patterned Wafer

-

Semiconductor

Semiconductor

-

Electronic Product

Electronic Product

- Polished Wafer

- Polished Wafer is a thin disc-shaped single crystal silicon product manufactured from high-purity poly-crystalline silicon by undergoing melting, crystal growth, cutting, polishing and washing processes. It is produced in diameters of 200mm/300mm and is usually used in the manufacture of memory semi-conductors such as DRAM/NAND Flash Memory.

- 200mmNon-memory chip

-

Logic (Driver IC)

Logic (Driver IC)

-

Sensor

Sensor

- 300mmMemory chip

-

DRAM

DRAM

-

Flash(NAND)

Flash(NAND)

- Epitaxial Wafer

- Epitaxial Wafer is made by adding multi-nanometer thick silicon single crystal layer on top of Polished Wafer. EPI Wafer is used in non-memory chips such as Logic Devices and CMOS image sensors. Its demand is gradually increasing for next-generation wafers.

- 200mmNon-memory chip

-

Analog (PMIC)

Analog (PMIC)

-

Power Discrete

Power Discrete

-

CIS

CIS

- 300mmNon-memory chip

-

MPU

MPU

-

CIS

CIS

-

Logic (Driver IC)

Logic (Driver IC)

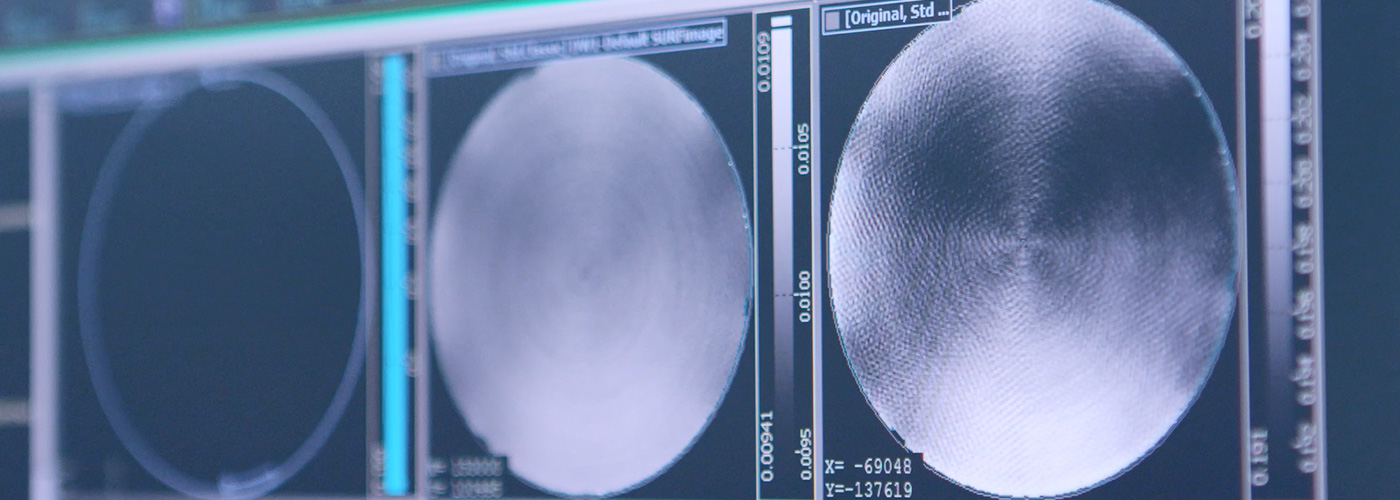

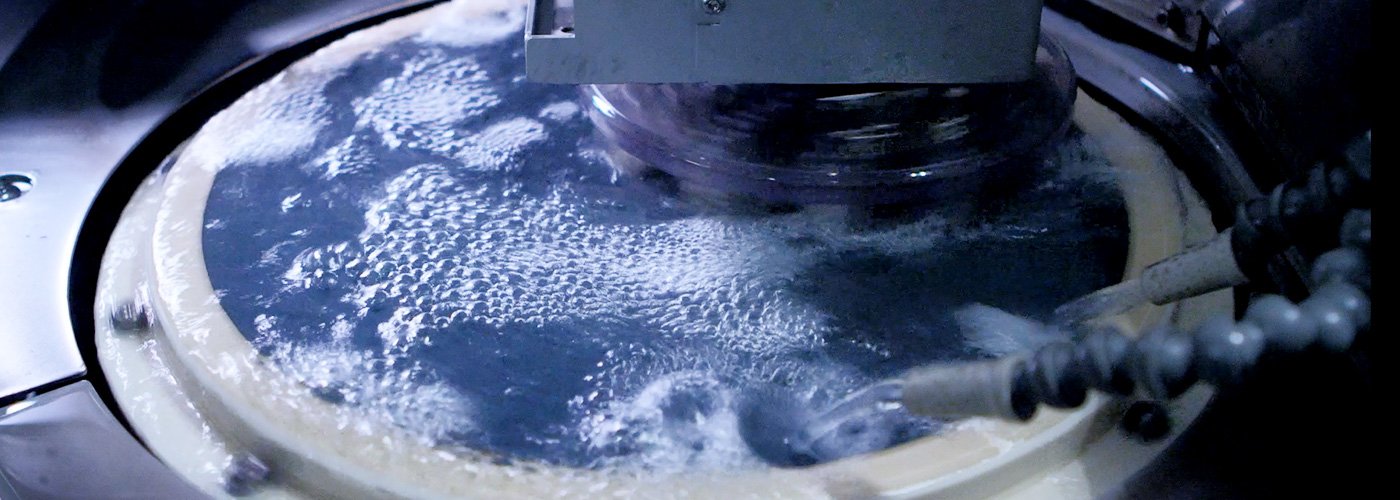

Core Technology

SK siltron offers advanced solutions for future markets that demand higher perfection and to

satisfy the various needs of global partners based on world-class defect free crystalline, super

flat surface control and small size particles control technology.