300mm Epitaxial Wafer

Manufacturing Process

-

-

1 POLY SILICON

STACKING - Process of filling high purity poly-crystal silicon in quartz crucible

-

1 POLY SILICON

-

-

2 INGOT

GROWING - Process where poly-crystal silicon is melted in high temperature then grown into single crystal ingot

-

2 INGOT

-

-

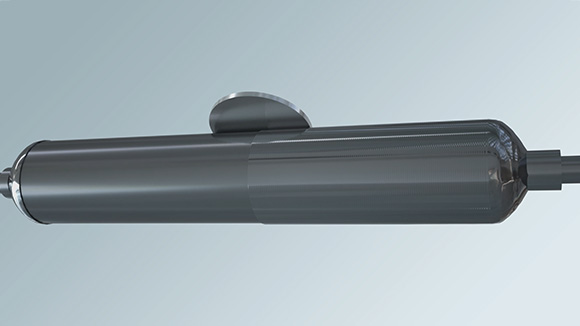

3 INGOT GRINDING

& CROPPING - Process of making the surface of ingot smooth then cropping into blocks

-

3 INGOT GRINDING

-

-

4 WIRE

SAWING - Process of cutting the ingot block into single wafers

-

4 WIRE

-

-

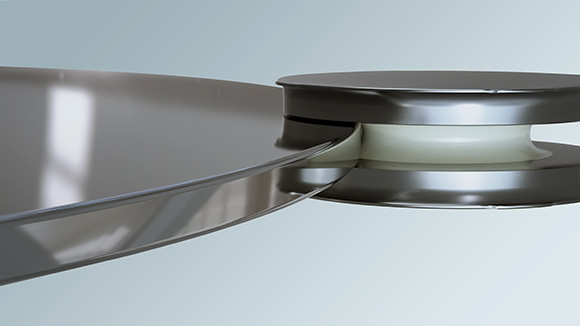

5 EDGE

GRINDING - Process of shaping the edge of the wafer

-

5 EDGE

-

- 6 LAPPING

- Process of making the surface of the wafer smooth and flat

-

- 7 ETCHING

- Process of eliminating process damages on wafer surface using chemical reaction

-

-

8 DOUBLE

SIDE GRINDING - Process of removing small bumps on the wafer surface

-

8 DOUBLE

-

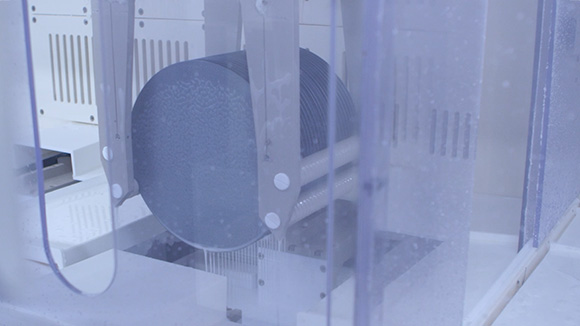

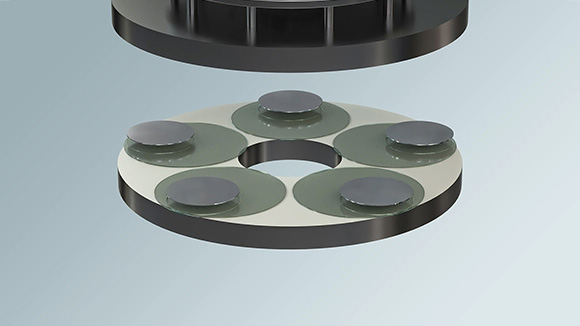

- 9 POLISHING

- Process of removing fine bumps on the wafer through precision processing

-

- 10 CLEANING

- Process of eliminating impurities on the wafer surface

-

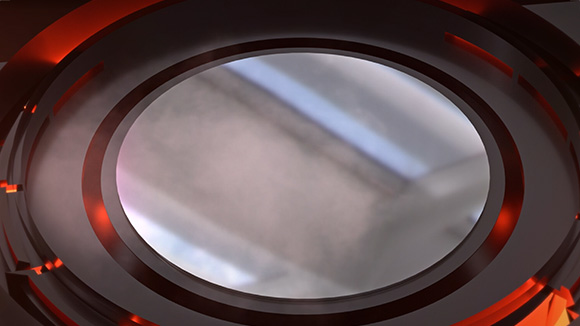

- 11 INSPECTION

- Process of inspecting the quality of wafer such as shape and flatness

-

-

12 PARTICLE

COUNTING - Process of inspecting defects in wafer surface

-

12 PARTICLE

-

-

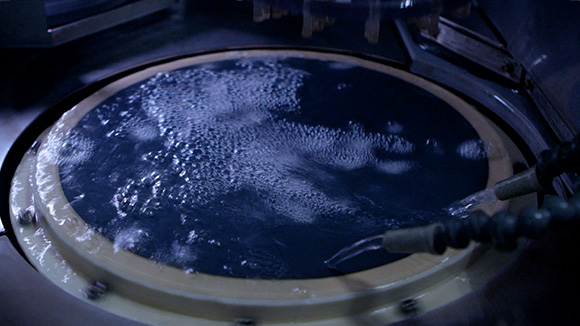

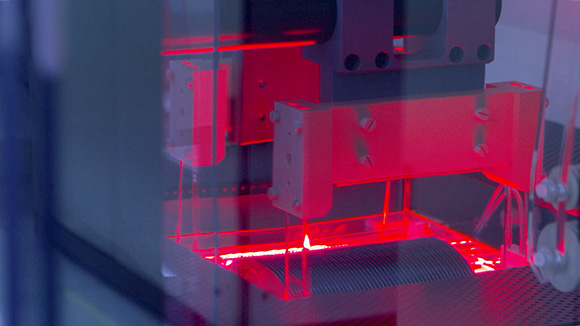

13 EPITAXIAL

GROWING - Process of adding silicon single crystal layer on wafers

-

13 EPITAXIAL

-

- 14 PACKING

- Process of packaging the product to protect it from shock, dust and humidity